Karlskoga Värmeverk - Steam Desuperheating

Any questions?

Fredrik Andrée

Process Engineer, Engineering dept.

Phone. +46 54-57 92 41

Sören Kindlund

Engineering Manager

Phone. +46 54-57 92 18

Existing desuperheaters of insertion type had poor functionality and needed replacement. The customer needed two sets of independent desuperheaters for redundancy.

Low steam velocity made the desuperheating inefficient. Thus simply replacing the desuperheaters with another insertion style nozzle would not solve the problem.

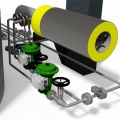

Askalon's solution was to deliver an inline desuperheater with liner for increased velocity and thus higher efficiency. Askalon supplied not only desuperheaters and valves but also drainage with steam trap and filter for water suply. Furthermore Askalon had responsibility for the installation regarding welding, NDE, etc.

Delivery time from order to installed product was 12 weeks. The customer is especially satisfied with the performance at low steam flows which is where they have had issues previously.